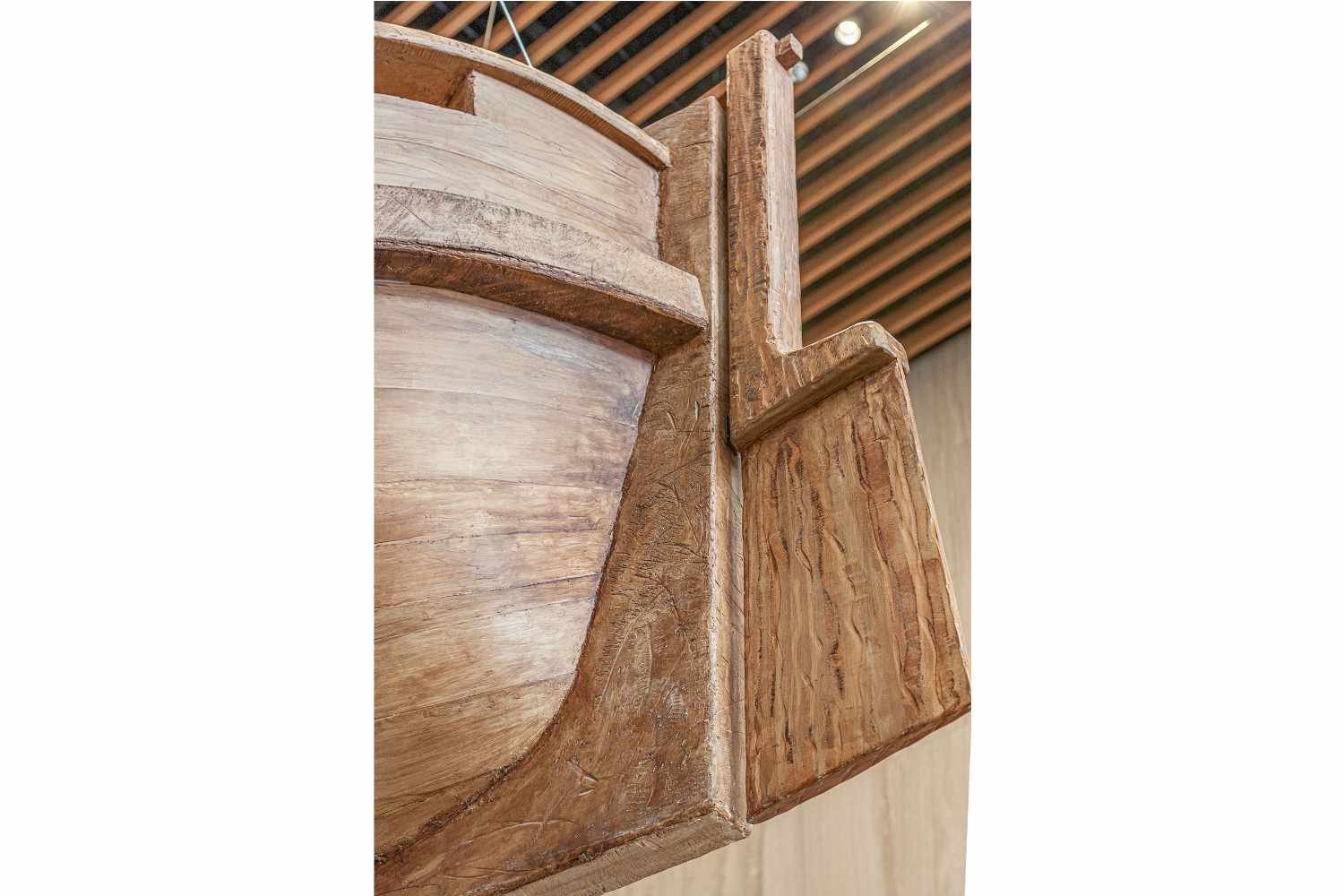

Rose Hill Packet replica at Parramatta Square

Today, the roundtrip from Circular Quay to Parramatta takes two hours by ferry. In 1789 it took a week to travel up and down the Parramatta River in the Rose Hill Packet.

Combining artistry and history Di Emme was commissioned by Chris Kenyon, representing Walker Corporation, to build a replica of the vessel for the lobby of 6 Parramatta Square.

How did the vessel get its name?

The Rose Hill Packet was the first European boat built in Australia. She was constructed in Sydney Cove by a team of convicts supervised by ship’s carpenter, Robinson Reid. ‘Rose Hill’ was as far as you could sail down the Parramatta River and ‘Packet’ comes from the boat’s use as a mail and supply boat.

Archives deliver picture of the past

Artist Chris Kenyon has been working with Walker Corporation to bring art and heritage elements to their Parramatta Square development. Chris’ extensive research included material from the archives of the Australian Maritime Museum, British Natural History Museum, and British Maritime Museum.

“From the archives, I had about 90% of how the original looked.” Chris said. “I even found a little watercolour by George Raper showing the boat in Sydney Cove.”

Chris designed a three-quarter stylised replica of the Rose Hill Packet and invested Di Emme with the task of bringing it to life.

Crafts combine in authentic model

To build an accurate 3-tonne replica that could hang safely in a lobby, Di Emme worked with a structural engineer, artisan carpenters, and a veteran sailmaker who knew the old techniques.

The convicts used axes and farm tools to build their vessel as the Australian hardwood damaged their boatbuilding tools. Di Emme recreated the roughhewn finish using hand tools, and tea stained the rigging and sails to add authenticity.

The boat has a metal armature clad in wood. When it was complete, the boat had to be cut in half to get it into the building, and then rejoined on site at Parramatta Square.

“The project took around a year. It was a challenging 3D fabrication project, but also one of our most rewarding ones,” said Di Emme’s Robert Gonda.